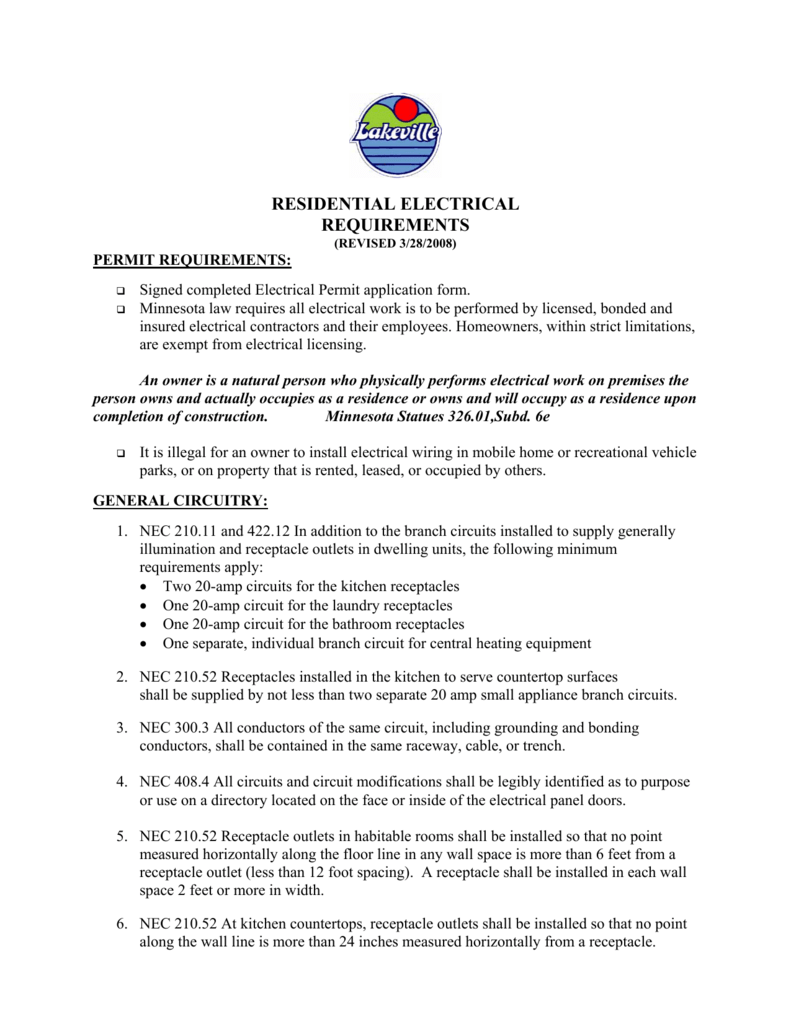

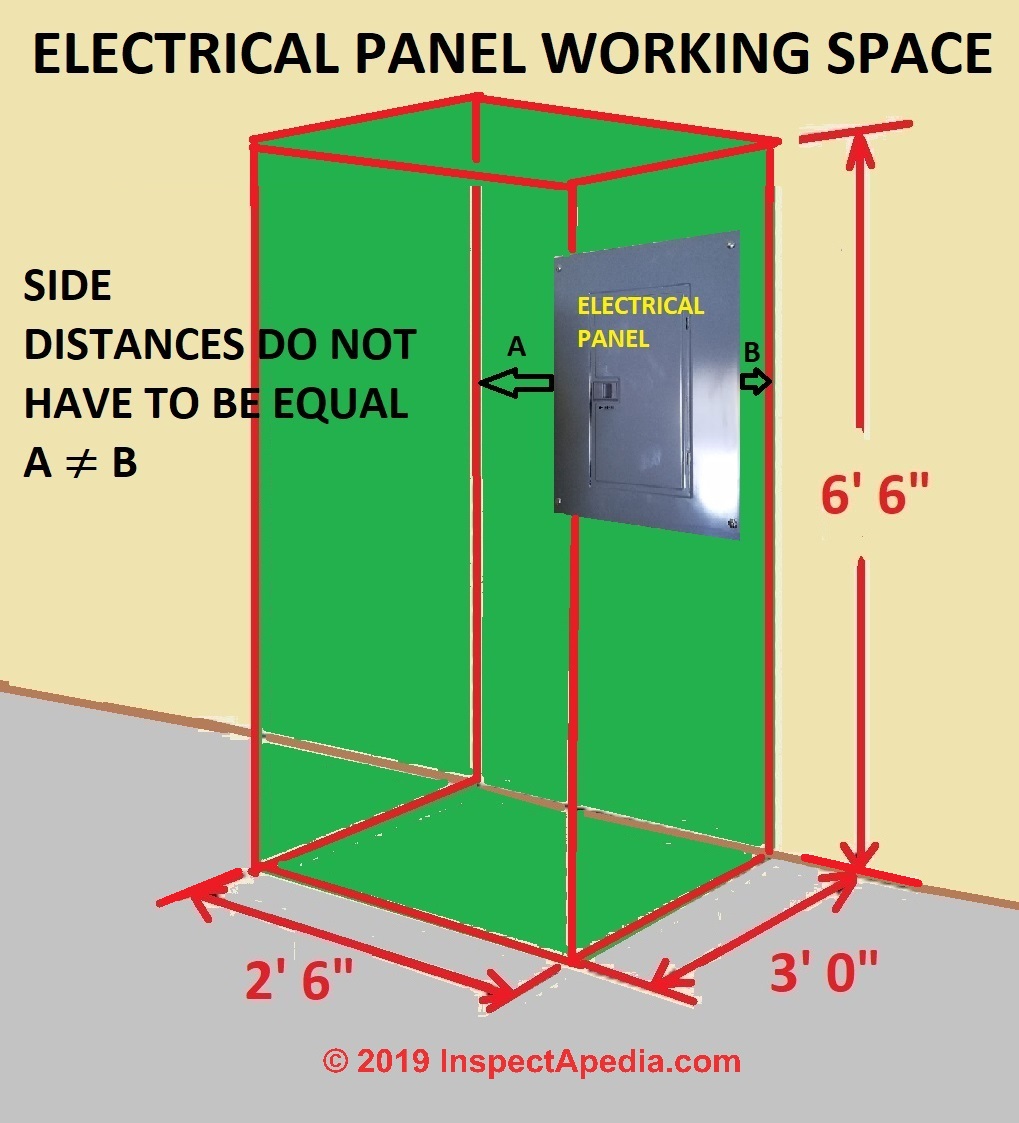

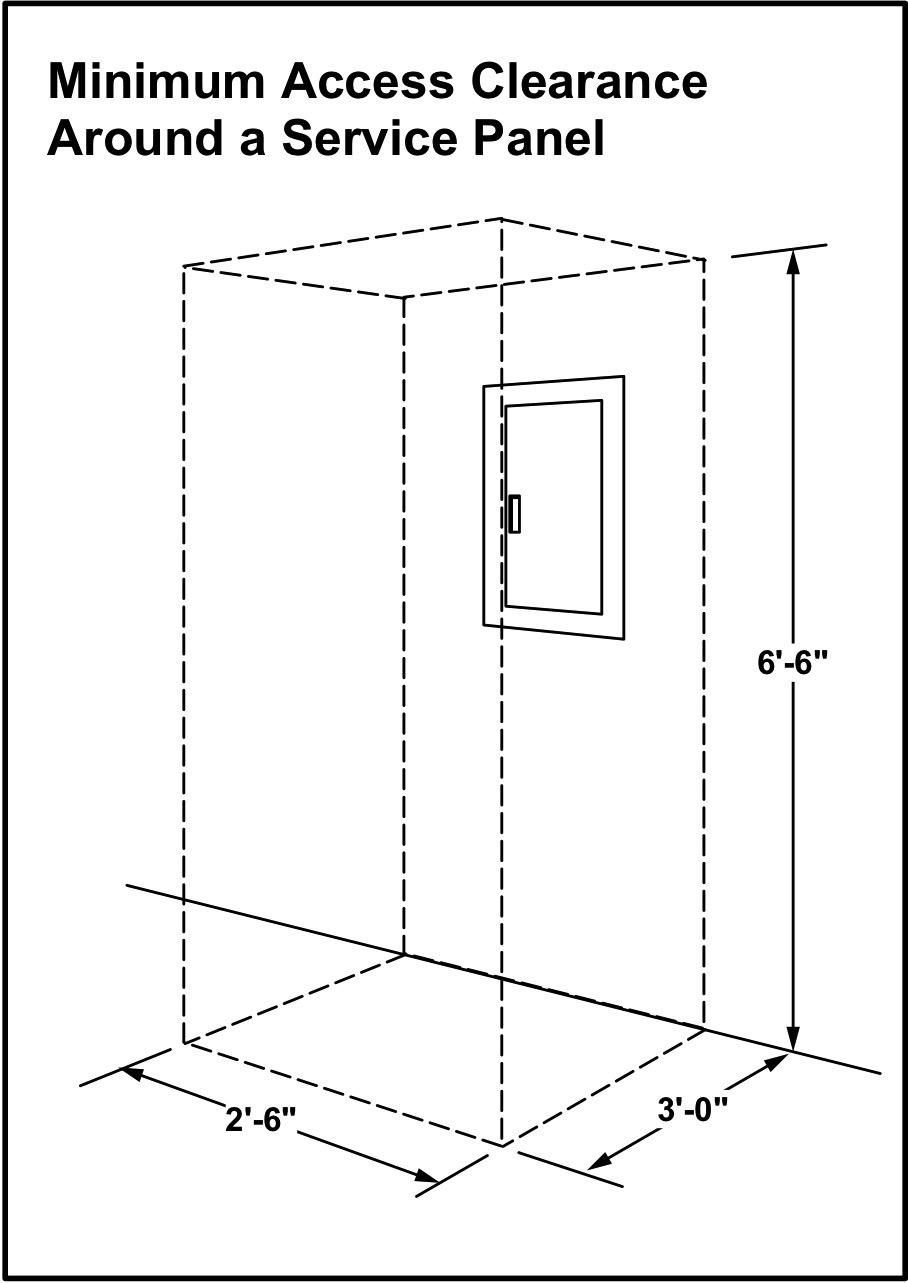

Article (A)(2)—Specifies that the width of the working space in front of the electrical equipment shall be the width of the equipment or 30 inches (762 mm), whichever is greater The goal is to prevent a worker from being unduly crowded when testing or maintaining equipment The width of the working space is a factor regarding worker Working space for equipment shall be provided and maintained per subsection (A) to permit ready and safe operation of such equipment The placement of bollards within working space, even if they are removable is prohibited, since they don't permit ready access toNational Electrical Code Top Ten Tips Article 110 Installation Requirements Spaces about electrical equipment (600V or less) Most people wrongly assume working clearances (depth of working space) are three feet Under some circumstances, the NEC requires them to be more

2

Nec 110.26 working space

Nec 110.26 working space- For example, minimum NEC workspace clearances would allow 1000Vdc inverters to be mounted on a wall with no space between them (provided the enclosure door opens 90 degrees), and there is sufficient width (30") to stand in front in the equipment, sufficient headroom (61/2'), and sufficient depth of working space (between 3' and 5Where rear access is required to work on deenergized parts on the back of enclosed equipment, a minimum working space of 762 mm (30 in) horizontally shall be provided Width of working space around electrical equipment NEC (A)(2) Working space around electrical equipment must be as wide as the equipment or 30 inches, whichever is greater

Www Glendaleheights Org Assets Pdf Comdev Permitpackets Residentialremodel Pdf

The wording of the article (and the commentary in the NEC Handbook) definitely seems to suggest that vfd's require working space However, the electrical inspector is allowing them to be buried behind the motors and pumpsEXHIBIT A working space with one entrance, which is permitted if the working space required by (A) is doubled see Table (A)(1) for permitted dimensions of X Where the entrance(s) to the working space is through a door, each door must comply with the requirements for swinging open in the direction of egress and Workspace If equipment may require examination, adjustment, servicing, or maintenance while energized, you must install it in a workspace in accordance with items (1), (2), and (3) of (A) The phrase "while energized" is the root of many debates

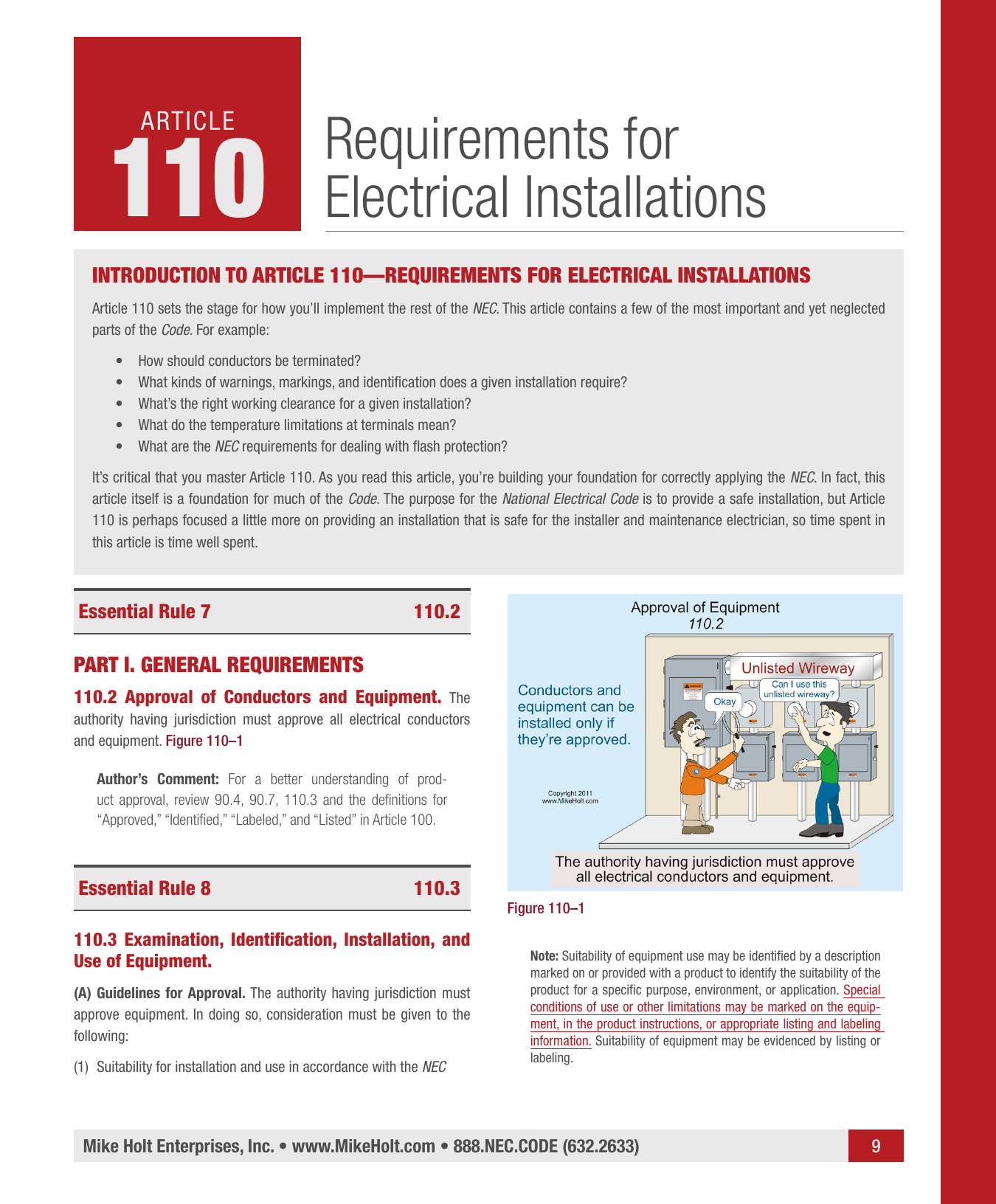

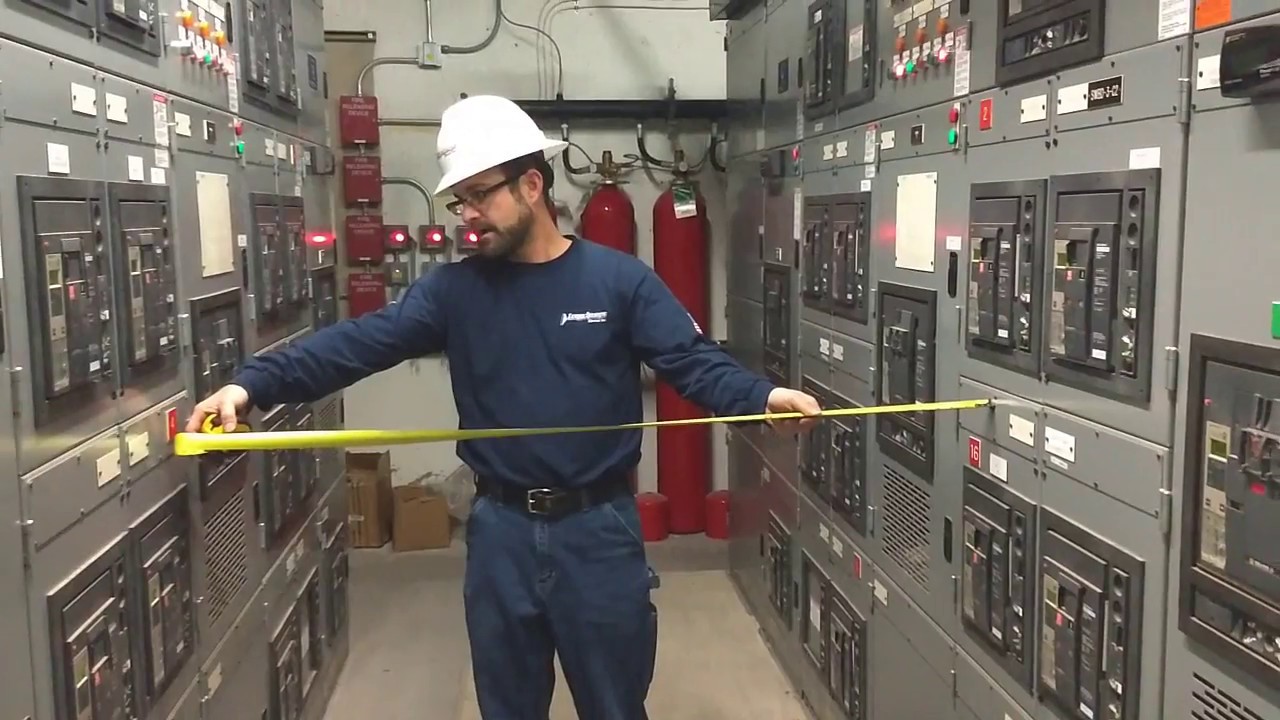

In the NEC, working space requirements are found primarily in Article 110 NEC applies to electrical equipment operating at 600 volts or less The primary requirement is that both access and working space must be provided and maintained for all electrical equipment (Photo 1)NEC (A) (2) states that "the width of the working space in front of the electrical equipment shall be the width of the equipment or 762 mm (30 in), whichever is greater" In addition, this work space shall permit at least a 90degree opening of the panelboard doorSpaces about Electrical Equipment Access and working space shall be provided and maintained about all electrical equipment to permit ready and safe operation and maintenance of such equipment (1) Depth of Working Space The depth of the working space in the direction of live parts shall not be less than

NEC (A)(3), (E) (e) The access and work space shall not be used for storage NEC (B) 3 Outdoor/Water/Moisture – Service Equipment and SubPanels shall not be located where subject to water or moisture on a regular basis or in large quantities, ie where exposed to lawn sprinklers or below a roof scupper NEC (F) 4The requirements in (A) (1) through (A) (3) of the National Electrical Code (NEC) deal with Code prescribed "working space" at electrical equipment—requirements that in most instances are considered by designers, installers and inspectors as eyeball situations;That is, some of the requirements are applicable only where the equipment "is likely to require examination, adjustment, servicing, or maintenance while energized" (A) Working Space

110 26 A 4 Limited Access

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

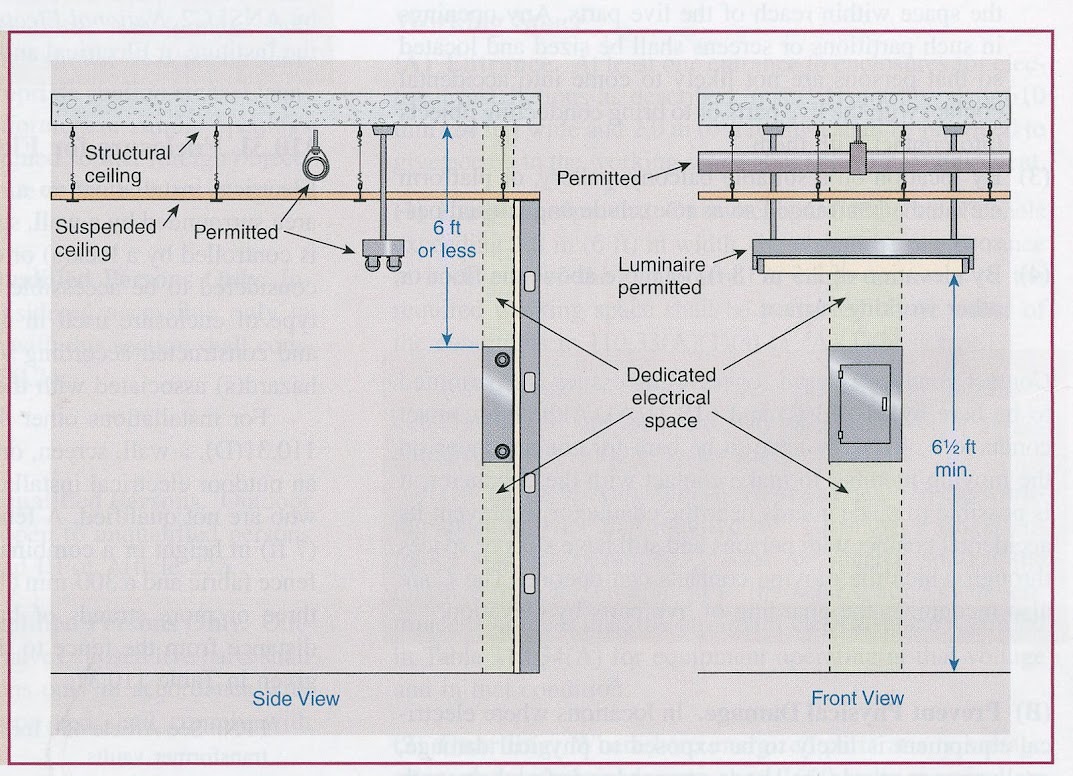

Also, storage is not allowed in the required working space, per NEC (B), the panel door must swing open a minimum of 90º, per NEC (A)(2), a panel cannot be located in a clothes closet, bathroom, or on stairs, per NEC (D,E,F), and the area in front of the panel must be illuminated, per (D)In the 1999 National Electrical Code (NEC), Section , Spaces About Electrical Equipment, consists of 1996 Section plus Subsection (f), Dedicated Equipment Space, relocated from 1996 Section 3844 " (f) Dedicated Equipment Space Code Violation NEC (A) 3 Height of Working Space Has to be 65 feet minimum or at least as high as the equipment "The work space shall be clear and extend from the grade, floor, or platform to a height of m (61/2 ft) or the height of the equipment" NATIONAL ELECTRICAL CODE, 14 Edition

Residential Electrical Requirements

Working Space For Electrical Equipment Iaei Magazine

NEC Table (A) (1) provides the minimum required work space depth for electrical equipment rated volts (to ground) that is likely to be examined or worked on while energized The minimum width of the working space is 30 in or the width of the equipment, whichever is greater, and all doors or panels must be able to open to 90 degrees or more This is the same as the general requirement found in (A) (2)Article (A)(2) Specifies that the width of the working space in front of the electrical equipment shall be the width of the equipment or 30 in (762 mm), whichever is greater The goal, obviously, is to prevent a worker from being unduly crowded when testing or maintaining equipment The width of the working space is a factor

Working Spaces Someone Help Mike Holt S Forum

National Electrical Code Nec United States Article 680 Requirements For Swimming Pools Spas Hot Tubs Fountains And Similar Installations Manualzz

If you have a room that meets the above requirements, (2) states that these electrical rooms must have an entrance/egress that is at least 24 inches wide and 65 feet tall at EACH end of the working space Working space requirements appear in Table (A) (1) Another addition appearing in here is that the equipment doorsThe national electric code • nec • adopted by the louisiana legislature as law • not a design manual • is a minimum standard nec article working space shall be provided and maintained about all electric equipment likely to require while energized working space shall beVisit http//wwwMikeHoltcom/14code to explore Mike's complete range of 14 NEC training products For over 35 years Mike Holt Enterprises has specialized

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

Space Program Part 1 Nec Chapter1 Article 110 26 Youtube

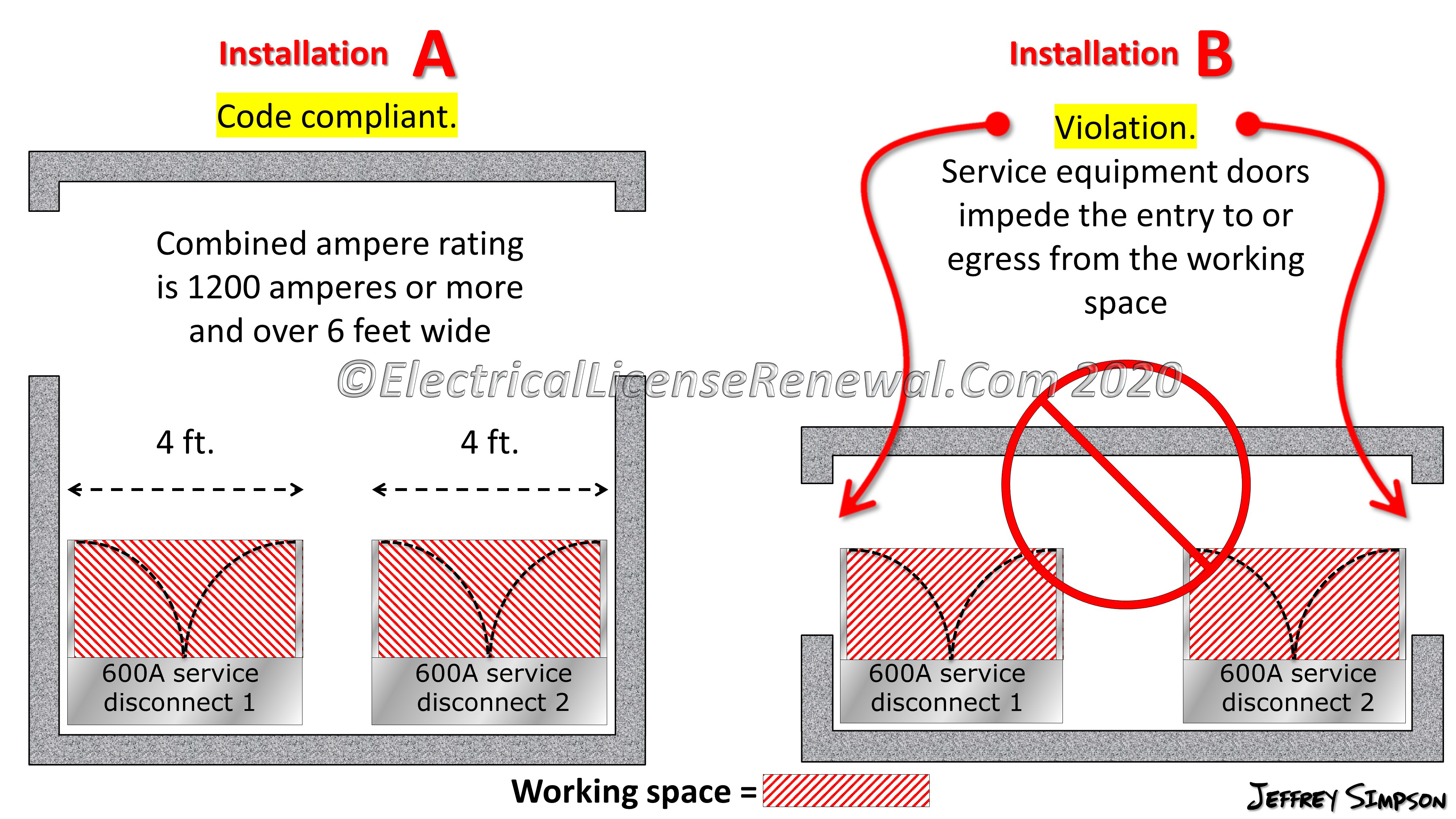

NEC (A) (3) Permits 6" extension into Working Space but NECHB Exhibit Taketh Away NEC (A) (3) is pretty clear in granting 6" extension of associated equipment into Working Space NECHB Exhibit and test CLEARLY disallows the above Yes, ,the working space requirement will indeed apply to this piece of electrical equipment per NEC (A) 11 (A) (A) Working Space Working space for equipment operating at 600 volts, nominal, or less to ground and likely to require examination, adjustment, servicing, or maintenance while energized shall comply with the dimensions ofIn the 17 NEC, the basic rule in Section (2) required an entry/exit at each end of the working space for large equipment when both of the following two circumstances were present Electrical equipment was rated 10 amps or more and contained overcurrent devices, switching devices, or control devices and

Requirements For Electrical Installations Pdf Free Download

1

However, the language in and (A) needs special evaluation and careful consideration when working onIndustrial control panels (NEC For the depth of the working space we will again refer to Table (A)(1) and base it on the voltage to ground and the conditions specified to determine the distance required, and all enclosure doors or hinged panels must be able to open at least 90 degrees The last Answer No The National Electrical Code Section (A) Working Space states in part, "Working space for equipment operating at 600 volts, nominal, or less to ground and likely to require examination, adjustment, servicing, or maintenance while energized " Transformers are not meant to be worked on while energized, therefore the work

Dedicated Equipment Space 110 26 E 1 Electrician Talk

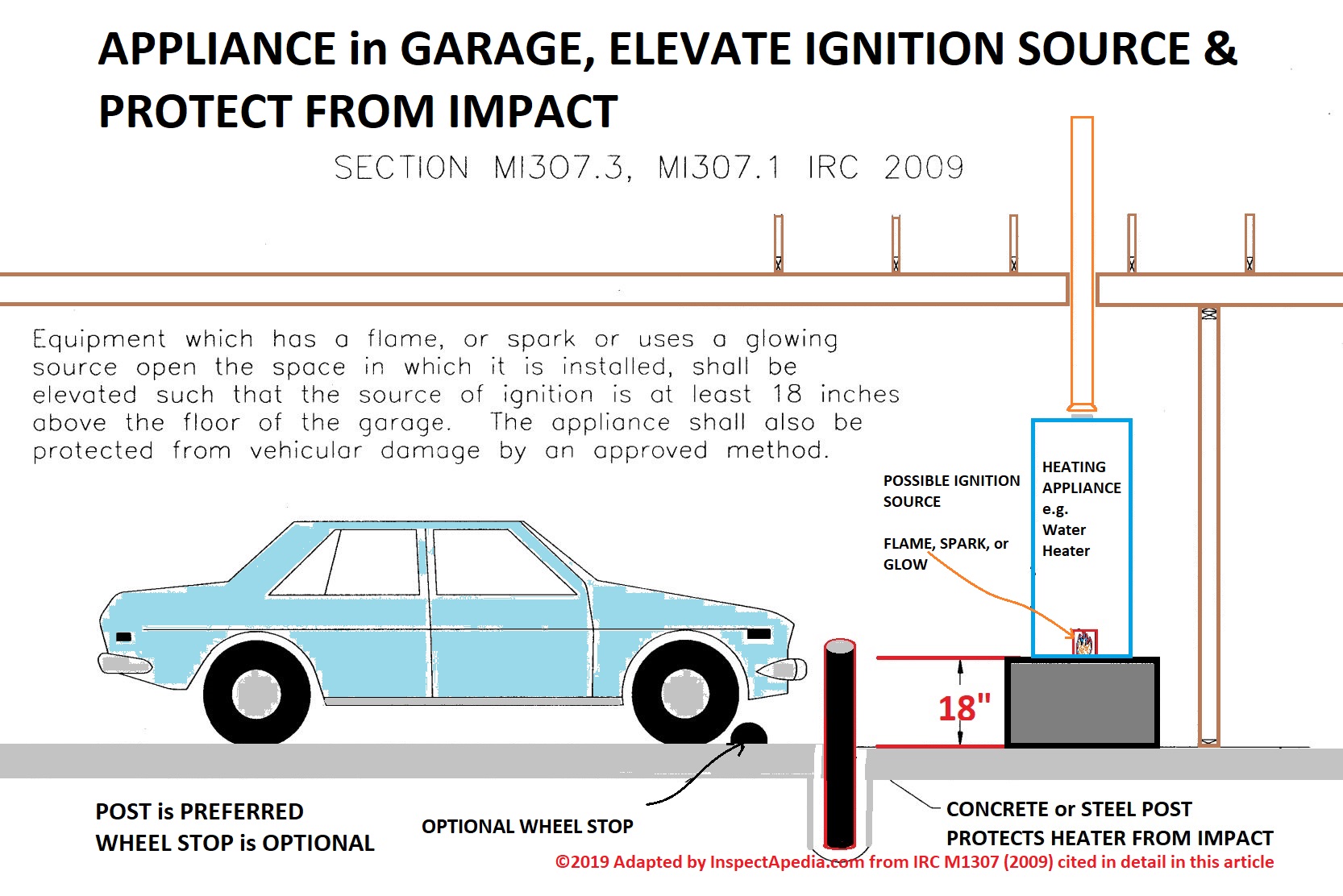

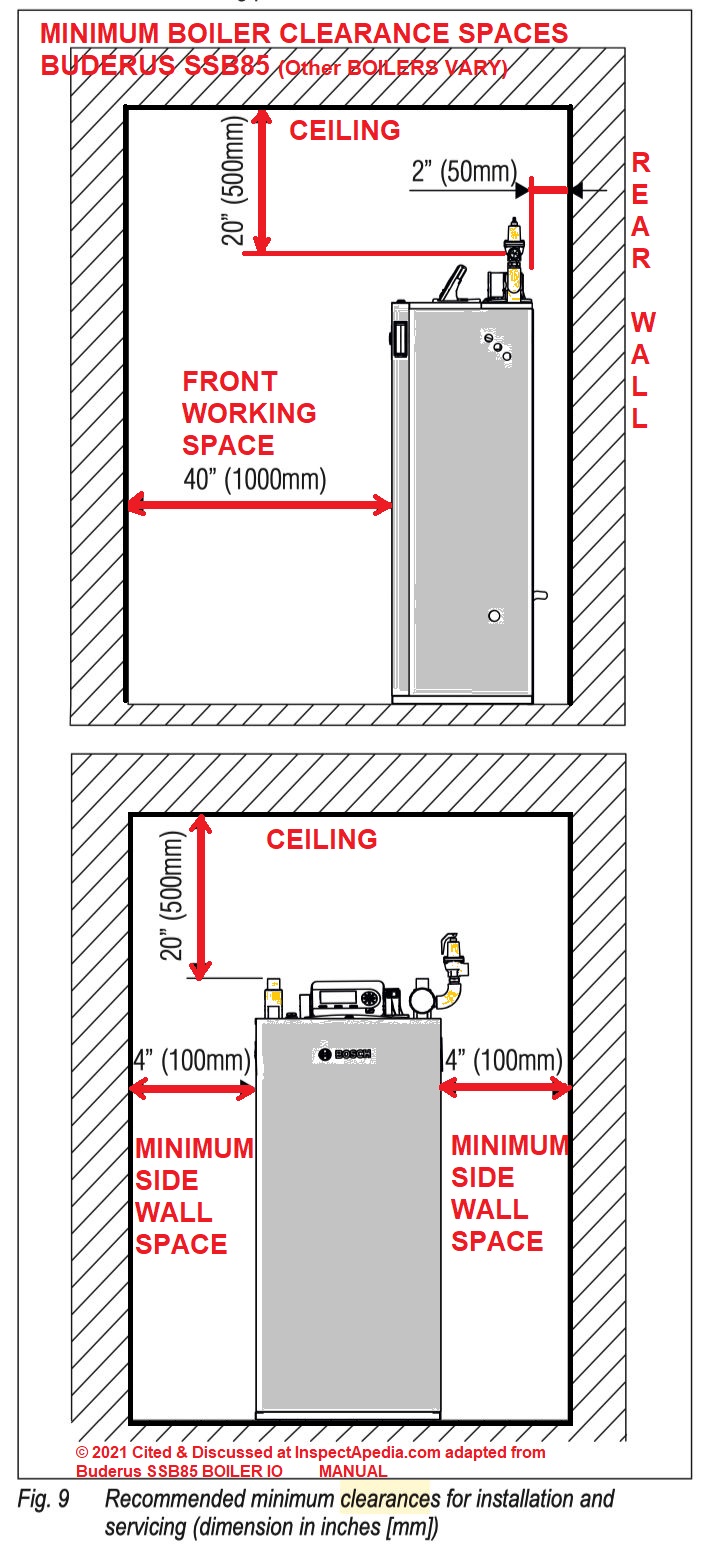

Clearance Distances For Building Features Mechanical Systemsindex To Sources Of Clearance Distances Or Separation Space Requirements At Residential Light Commercial Properties

RE NEC Workig Clearance Requirements rcw retired EE (Electrical) 7 Jun 12 17 My interpretation is that working space depth is only doubled if there is only one egress from the space NEC article (A) (1) condition 3 states that exposed live parts on both sides of the working space require minimum clear distance of 4ft NEC does not explain the dead front panel working space requirements between panels Under all circumstances, there are no live parts exposed to persons entering the electrical room NEC 14 Article (B) Clear Spaces Working space required by this section shall not be used for storage When normally enclosed live parts are exposed for inspection or servicing, the working space, if in a passageway or general open space, shall be suitably guarded

National Electrical Code Changes For 08 Manualzz

Www Glendaleheights Org Assets Pdf Comdev Permitpackets Residentialremodel Pdf

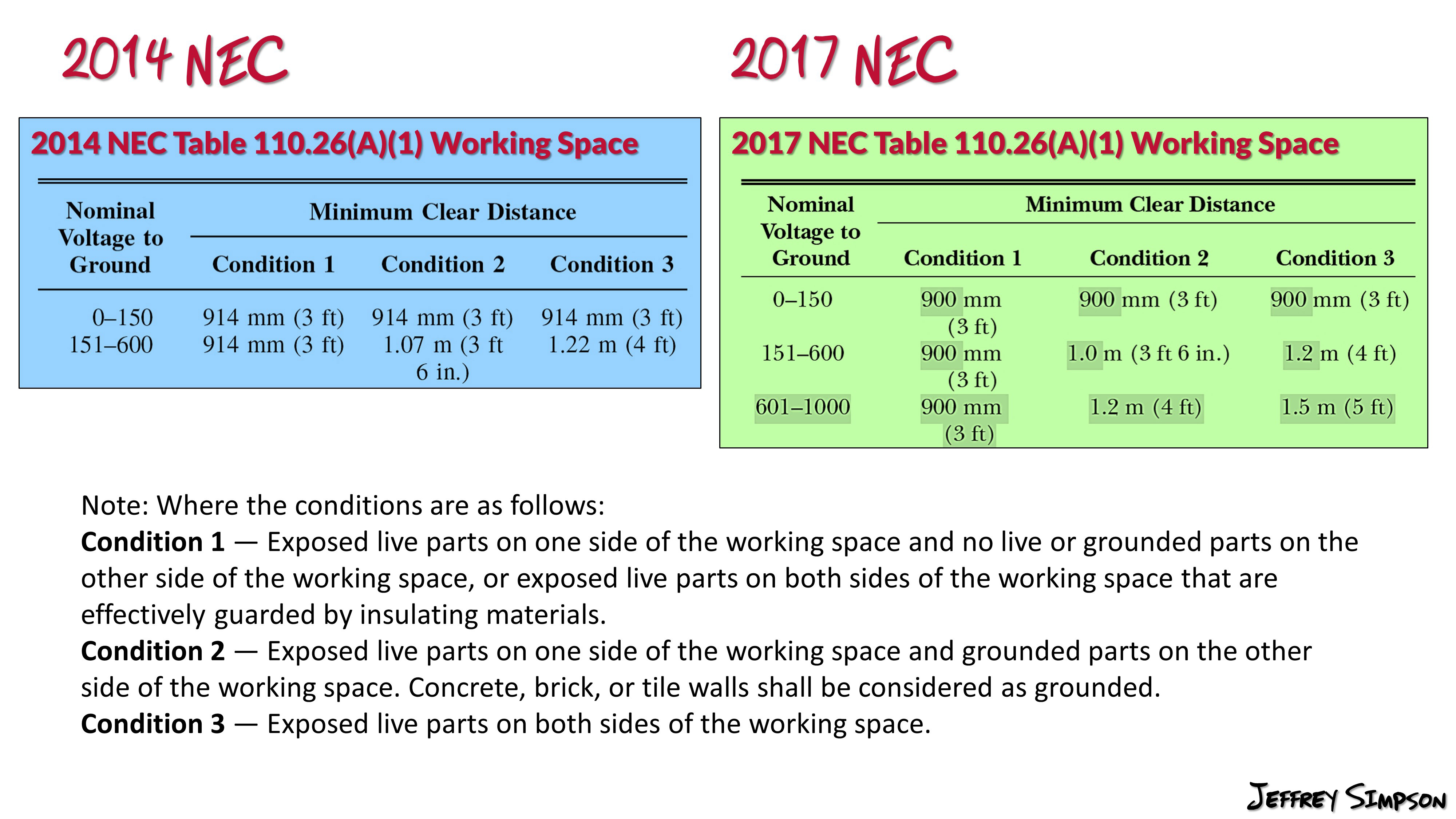

Egress and working space for rooms containing electrical overcurrent devices, switching devices, or control devices shall be in compliance with the International Fire Code and Section of NFPA 70 Background 15 IFC 6053 Working space and clearance A working space ofnot less than 30 inches (762 mm) in width, 36Table (A)(1) Working Space VoltagetoGround Condition 1 Condition 2 Condition 3 0–150V 3 ft 3 ft 3 ft 151–600V 3 ft 3½ft 4 ft • Condition 1—Exposed live parts on one side of the working space and no live or grounded parts, including concrete, brick, or tile walls are on the other side of the working spaceNEC Requires access and working space be provided about all electrical equipment to permit ready and safe operation and maintenance of such equipment Our current staff consensus and State historical position is that a removable barrier meets the intent of the requirement in NEC

Www Ncosfm Gov Electrical Working Space And Clearances Open

110 26 E 2 Dedicated Equipment Space Outdoors

EXHIBIT The two distinct indoor installation spaces the working space and the dedicated electrical space EXHIBIT Illustrates the working space in front of the panelboard by (A) No equipment, electrical or otherwise, is allowed in the working space EXHIBIT The working space in front of a panelboardWork Space and Guarding The requirements of are conditional, just like the requirements in ;Author's Comment The working space requirements of don't apply to equipment included in Chapter 8— Communications Circuits 903 (2) Width of Working Space The width of the working space must be a minimum of 30 in, but in no case less than the width of the equipment

Http Www Teces Org Docs 443 Pdf

110 32 Workspace About Equipment

Analysis Section (A) (3) describes the height of the working space and allows for electrical equipment to intrude into the working space for a maximum depth of 6" This can often be seen in equipment rooms that have a wireway protruding outward above or below a panelboardGreetings Mr Design Engineer, Thank you for submitting your question with regards to the proper application of section (2)(a) as it pertains to establishing a compliant and safe single entrance to and egress from large electrical equipment rated 10 amps or more and over 6 feet wide that contain overcurrent devices, or control devices, or switching devices This double the working clearance and minimum clearance to the entrance from the electrical equipment provides the ability to step back into the "double" working space zone provided and effectively egress out the opening without having to traverse through the working space clearances as defined in section (A)(1)

Www Southstpaul Org Documentcenter View 867 14 Electrical Residential Checklist Brochure Bidid

Webinar Electrical Conductors And Equipment Spaces Article 110 26 110 34 Of The Nec Youtube

Does (A) apply to variable frequency drives controlling hvac related pumps?Calculations for service equipment (NEC ); NEC requires working clearance in front of equipment likely to require calibration, testing, or adjustment while energized This means a 30 by 36 inch space (or larger) in front of panels, access panels on HVAC equipment and fused disconnects Does this requirement extend to non

Www Newbrightonmn Gov Media Permits Electrical information for homeowners Nov Pdf

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

The working space is defined in all three dimensions depth, width, and height Some of the working space requirements found in Section (NEC05) include (A) Working Space Working space for equipment operating at 600 volts, nominal, or less to ground and likely to require examination, adjustment, servicing, or maintenance whileAs outlined in NEC Table (A),these are Condition 1 When there are (i) exposed live parts on only one side of the working space, (ii) grounded live parts on the other side of the working space, or (iii) when both sides of the working space are sufficiently insulated Requires 3 8 ft depending on voltage from 1001V to above 75 kV The clear working space that is required by the first sentence as described in (A) may be eliminated only where examination, adjustment, servicing and maintenance are not "likely" to occur when energized exposed live parts, etc, are present" , 0549 PM #2

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

Working Space For Electrical Equipment Iaei Magazine

Provide sufficient working spaces and clearances for batteries Working space shall be measured from the edge of the battery cabinet, racks, or trays, (NEC 4809, ) Spaces about the ESS shall comply with NEC Working space shall be measured from the edge of the ESS modules, battery cabinets, racks, or trays, (NEC )Reference National Electrical Code (NEC) Table (A)(1)) Condition 1—Exposed live parts on one side of the working space and no live or grounded parts, including concrete, brick, or tile walls are on the other side of the working space

Nec Changes Part 2 Space In Electrical Rooms And Panic Hardware

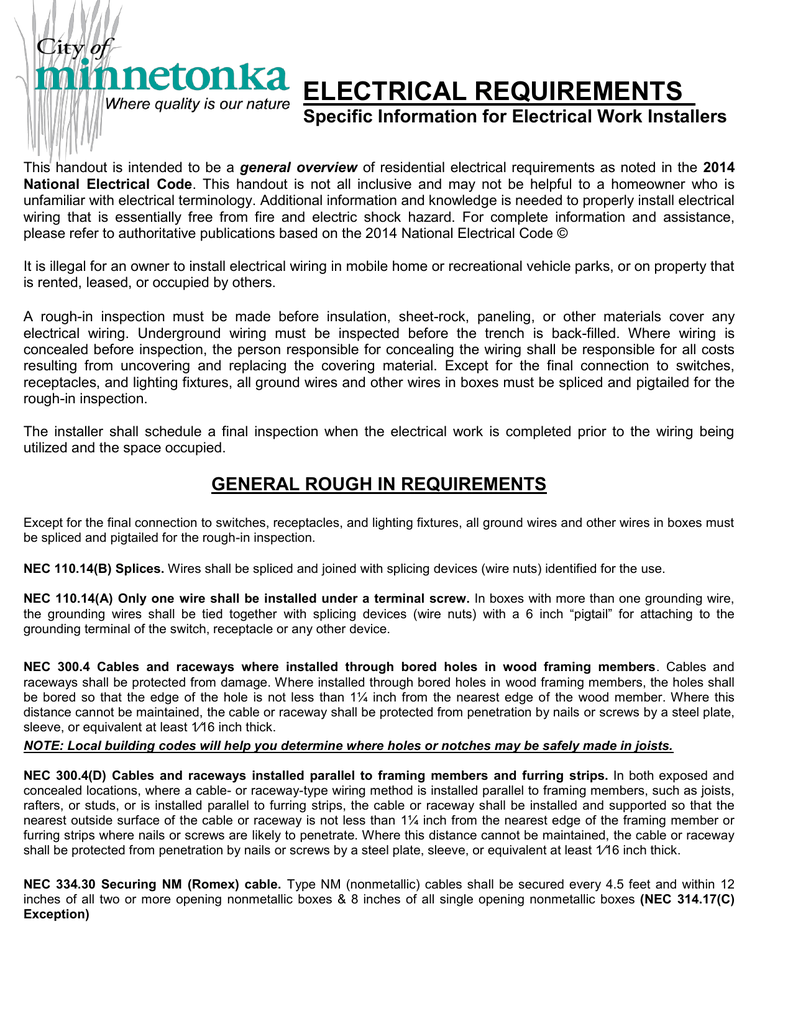

Electrical Requirements

2

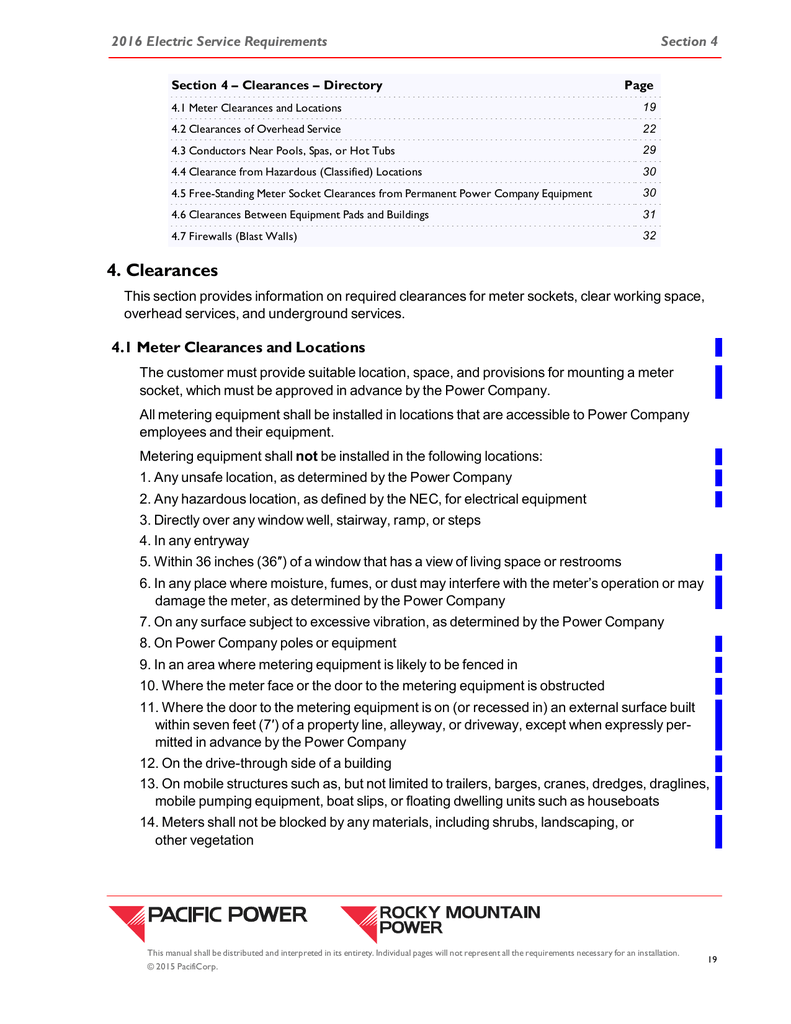

Chapter 4 Clearances

Working Space For Electrical Equipment Iaei Magazine

Requirements For Electrical Installations

Working Space For Electrical Equipment Iaei Magazine

Www Siouxfalls Org Media Documents Building Nec W Track Changes W Commentary Ashx

Http Www Dli Mn Gov Sites Default Files Pdf Nec Committee Min Pdf

Electrical Requireme

Ewh Ieee Org R3 Atlanta Ias 16 17 Presentations 17 03 09 Ieee atl Rb Nec17 Pdf

Glendaleheights Org Assets Pdf Comdev Addendums Residentialelectric Pdf

Working Space For Electrical Equipment Iaei Magazine

2

Clearance Distances For Building Features Mechanical Systemsindex To Sources Of Clearance Distances Or Separation Space Requirements At Residential Light Commercial Properties

Entrances To And From For Electrical Equipment Rooms And Pages 1 39 Flip Pdf Download Fliphtml5

Electrical Code Requirements Photovoltaic System Electrical Wiring

1

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

General Installation Requirements Part Xxi Electrical Contractor Magazine

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

110 26 C 3 Entrance To And Egress From Working Space Personnel Doors

Www Richfieldmn Gov Document Center Department Community development Permits inspections licenses Building code handouts Electrical Pdf

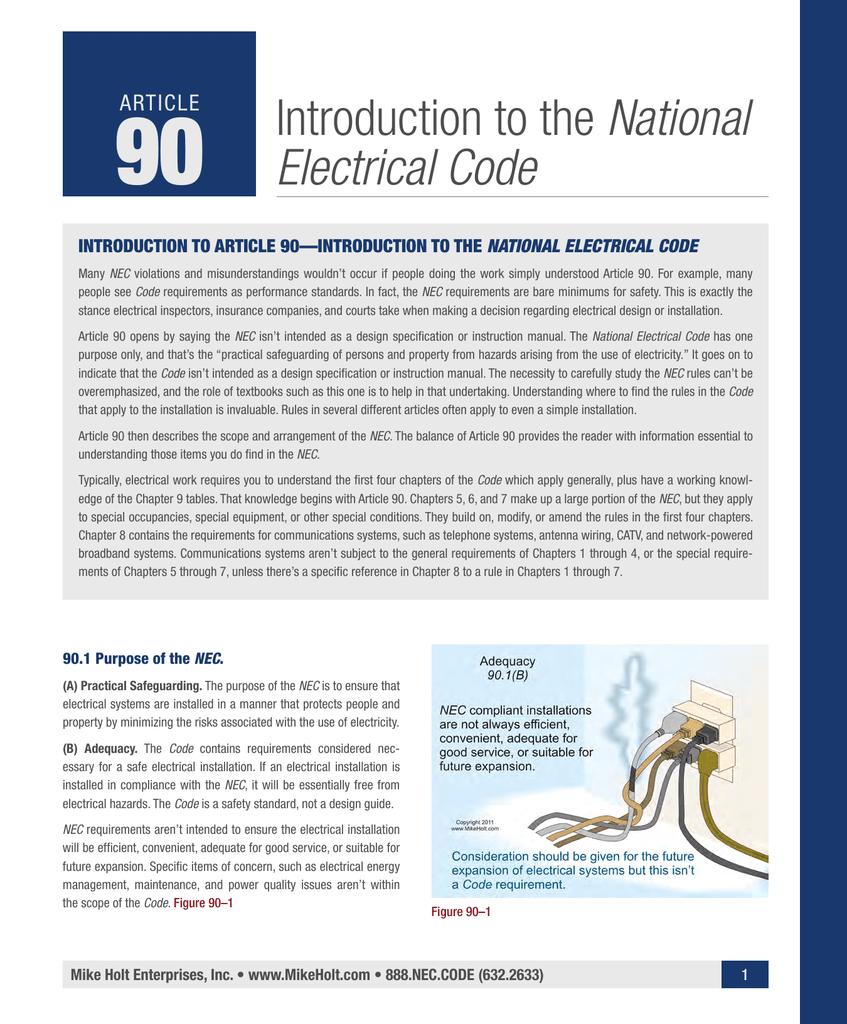

Introduction To The National Electrical Code

Http Www Illowaicc Org Uploadedfiles Illowa Newservicewdisconnectv6 Pdf

Spaces About Electrical Equipment Nec Violation Example Carelient

Q Tbn And9gcqkkcyyfzdwu78lzw9uw5uk5tgqnn1j93hjfqj2 2myghfchgsv Usqp Cau

Www Nfpa Org Assets Files Aboutthecodes 70 70 010 Ropdraft Pdf

Master The Nec Podcast Podcast Podtail

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

Sample Pages

Www Siemens Com Download Btlv

Www Nfpa Org Assets Files Aboutthecodes 70 70 016 Nec Frreport Pdf

110 26 C 2 Large Equipment

Www Eaton Com Content Dam Eaton Products Medium Voltage Power Distribution Control Systems Vacclad W Pages Electrical Equipment Floor Space Ap0007en Pdf

Working Space In The Nec Youtube

Wsr 17 06 052 Proposed Rules Department Of Labor And Industries Filed February 28 17 9 36 A M Original Notice Preproposal Statement Of Inquiry Was Filed As Wsr 16 19 075 Title Of Rule And Other Identifying Information Proposed

Level Measurement High Voltage Electrical Wiring

2

Electrical Inspection Electrical Wiring Building Technology

Understanding Fire Alarm Systems Iaei Magazine

Http Www Teces Org Docs 445 Pdf

Andrew Zonenberg Hey Slcairport I Think This Might Be An Electrical Code Violation Nec 110 26 B Working Space Required By This Section Shall Not Be Used For Storage Main Terminal Between

Working Space For Electrical Equipment Iaei Magazine

Nec Working Clearance Youtube

Http Www Rld State Nm Us Uploads Files 14 nmec 14 10 4 Pdf

Table 110 26 A 1 Working Spaces

Table 110 26 A 1 Classes4contractors

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

Electrical Panel Equipment Working Space Clearance Distances U S Nec Article 110 26

Subpanel Working Clearance Contractor Talk Professional Construction And Remodeling Forum

Www Mecknc Gov Luesa Codeenforcement Documents Electrical meetings 18 Pdf

Inspectionnews Home Inspection

Www Mecknc Gov Luesa Codeenforcement Documents 19 electrical code academy meetings Pdf

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

Subpanel Working Clearance Contractor Talk Professional Construction And Remodeling Forum

Dsps Wi Gov Documents Programs Udc Electricalcoderemindersforbuildersbuildinginspectorsfinal Pdf

Www Discoverosseo Com Index Php Download File View 1949 136 74

When Did The Requirement For Clearance In Front Of An Electrical Panel Become Code

Www Ci Stcloud Mn Us Documentcenter View Electrical Handout 14 Nec Bidid

General Installation Requirements Part Xxii Electrical Contractor Magazine

2

Q Tbn And9gctb3eskfovps5xjkyj0dps2mlerpqsoygddeegmf2 Ifiv29hx4 Usqp Cau

General Requirements Of The Nec Ec M

Entrances To And From For Electrical Equipment Rooms And Pages 1 39 Flip Pdf Download Fliphtml5

General Requirements Of The Nec Ec M

Requirements For Electrical Installations Pdf Free Download

Nec Working Space Requirements Live Stream Youtube

Nec Article 6 11 50 15 54 Asme A17 Series Of Elevators Escalator Standards

Electrical Safety Limits Of Approach 70e Phoenix Arizona

General Requirements Of The Nec Ec M

Webinar Electrical Conductors And Equipment Spaces Article 110 26 110 34 Of The Nec Youtube

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

General Installation Requirements Part Xxxv Article 110 Electrical Contractor Magazine

Seips Tech Tips Workspace Clearances For Solar Pv Systems Sei Professional Services

Documen Site Download Slide 1 5aca9fff3f92c Pdf

Wsr 17 06 052 Proposed Rules Department Of Labor And Industries Filed February 28 17 9 36 A M Original Notice Preproposal Statement Of Inquiry Was Filed As Wsr 16 19 075 Title Of Rule And Other Identifying Information Proposed

General Installation Requirements Part Xxxv Article 110 Electrical Contractor Magazine

Will This Work For Breaker Box Location After Remodel Home Improvement Stack Exchange

No comments:

Post a Comment